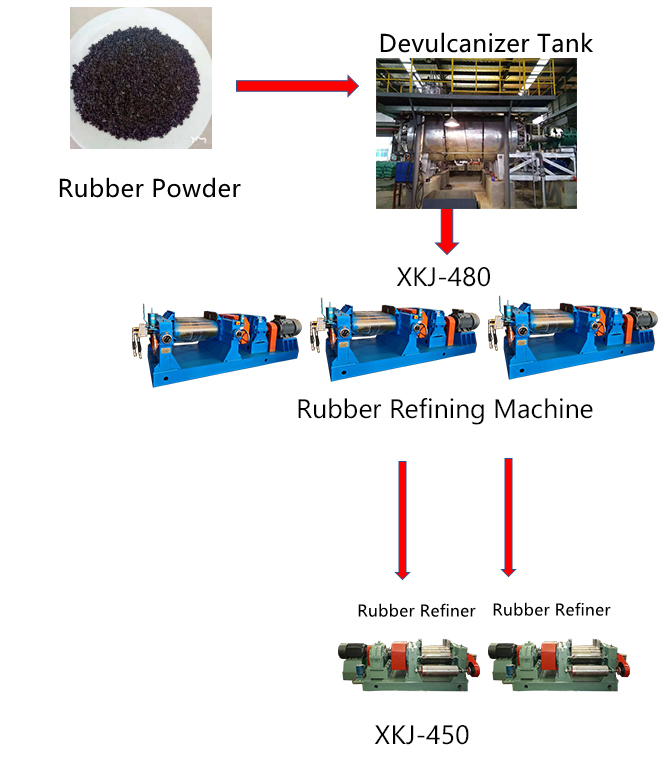

Rubber Refiner is rolling after desulfurization rubber powder,

change the physical form, and remove hard impurities contained in

the reclaimed

rubber. Before and after the roll surface is smooth, like a waist

drum. Refining machine during operation, It can be hard rubber

impurities from the roller center to both ends. Impurities gathered

at the edge of the roller,

Then use knife remove to impurities on the edge of roller. Roll

adopts the vanadium titanium alloy chilled cast iron, the surface

is hard wearresisting, inner cavity machining, the roll surface

temperature

uniformity. The machine is equipped with an emergency brake, When

emergency occurs, pull the pull rod, the machine immediately brake,

safe and reliable. Driving system consists of NGW hardened tooth

surface reducer, compact structure, low noise, high efficiency,

longservice life.

Brief desctription: 1. rollers,chilled cast iron 2. Water cooling

system 3. hardened reducer ,bearing bush 4. welded or casting base

5. HS of rollers:68-72

Features: 1. Rollers: the roller adopts chilled cast iron alloy

(LTG-H) with 68-72 HS ,after quenching and precision processing

with long service life,so the surface is hard and wearable;it is

harder than others the commom is 72HS. 2. Emergency Stop Device:The

machine is also equipped

with emergency stop buttons or emergency pull rod. When an

emergency happens, just press the emergency button or pull the pull

rod,the machine

will stop immediately. It is safe and reliable; 3.Motors: We always

use OMRON,SIMENS ect brand electric parts or you can choice the

ordinary brand.all the motor is high quality and effiency,save

energy,low noise,small vibration. 4. Overload: This open mixing

mill has overload protection devices, Machine will be stopped

automatically, if overloaded; 5. Gear Box:The transmission system

adopts hardened reducer,which has a compact

structure with higher transmission efficiency,lower noise and

longer service life(ZQ reducer and planetary reducer is optional);

6. Bearing Bush:Double Row Spherical Roller Bearing can save energy

by 20-30%(Nylon Bushing and Brass Bush is optional); 7.

Structure:The base and frame are welded and treated by annealing

for stress relieving; 8. Sealing Device:The seal structure with

special design can eliminate the leaking phenomenon of lubricating

oil; 9.Cooling system:circulation of steam and tap water can be

through rollers to control the temperature 10.Safe Electrical

Parts: All electrical connections are safe:short circuit is not

possible by any means.